Define the two tags num_L and num_S as Global memory INTs as shown in the next figure. All rights reserved. Assign the inputs and outputs as shown in the next figure. Let the PV input at 0 (as a constant) and assign the Stop bit to the R input. We will use the state of the Auto_mode bit as a condition to allow the functions well program to be executed. Open the Bit Logic Operations folder then drag and drop a normally open contact and a Set instruction on the line of Network 1. Explore our courses, 2022 SolisPLC. Calculate the percentage of small/large boxes. Siemens has gone to great lengths to make its development environment as enjoyable to use for beginners as it is for veterans. Now that we have defined all the machines specifications, we can start writing our PLC program. First, we will define the conveyors A behavior (large boxes).

You can find the normally closed contact in the Bit logic operations folder. To avoid that, we just have to add a Reset timer instruction just before the IN input. For this case, we want the timer to run for 5 seconds.

Now we need to add instructions that will change the state of Auto_mode to 0 when we press the stop button. If the condition is verified, the program proceeds to execute the rest of the line. This is the main block of the project (OB1 for Organization Block 1). And define them as Auto_mode and Large_box. The normally closed contact is a bit interrogation. Add an Auto_mode NO contact in Network 9 followed by a DIV (Divide) instruction. Let the DBs number be set automatically. In our case, we want to stop the machine when the total number of boxes reaches 1000.

In our case, we want to stop the machine when the total number of boxes reaches 1000.

ladder plc programming examples The machine must stop once at 1000 boxes. Since we already have an Auto_mode bit interrogation, no need to add another one. Define it as Global memory. Let the software initiate the project until the projects interface appears. Drag and drop the instruction, name it Large_box and define it as a Local temp BOOL. To do this, add an Auto_mode NO contact followed by a CONVERT instruction to Network 8. The start button, stop button, and both sensors (PE_Low and PE_High) are wired to 4 PLC digital inputs (from I 0.0 to I 0.3). If its state is 1, the program proceeds to execute the rest of the line. Once done, click on Define. Right after the Large_box contact, add a CTU (CounterUp) instruction and name it CounterL_DB (in the call options window). We can simply add a new branch right after the interrogation. Now we just have to add an assignment instruction right after the Q output. In this tutorial, we will be focusing only on the basic instructions. First thing is to give it a tag. For this, add a MUL (Multiply) instruction. The PT input requires a TIME data type. This can be accessed any time by clicking on the Instructions side tab. Start by launching TIA Portal. The reset instruction changes the state of its associated bit to 0. Right after, add an assignment instruction, name it Motor2 and define it as a Global output BOOL. If the instruction is kept like that, itll cause a malfunction in the machine. If the previous logic result is 0, the associated bit will be set to 0. Once on the device configuration, click on Add a new device, open the folders Controllers -> SIMATIC S7-1500 -> CPU -> CPU 1511-1 PN, and select the 6ES7 511-1AK02-0AB0 CPU. You can find the Reset timer instruction in the Timer operations. Name the timer timerB_DB and define the assignment instruction as Motor1. Counting the number of small/large boxes and their total. Repeat the same actions we just did but use a normally close contact for PE_High. First, add an Auto_mode NO contact followed by two branches: one leading to a Large_box NO contact and the other to a Small_box NO contact in Network 6 as shown in the next figure. You can reset the counter to its first value by setting a 1 in the R input. The CTU instruction counts the number of times the CU input is set to 1.

Since we already have an Auto_mode bit interrogation, no need to add another one. Define it as Global memory. Let the software initiate the project until the projects interface appears. Drag and drop the instruction, name it Large_box and define it as a Local temp BOOL. To do this, add an Auto_mode NO contact followed by a CONVERT instruction to Network 8. The start button, stop button, and both sensors (PE_Low and PE_High) are wired to 4 PLC digital inputs (from I 0.0 to I 0.3). If its state is 1, the program proceeds to execute the rest of the line. Once done, click on Define. Right after the Large_box contact, add a CTU (CounterUp) instruction and name it CounterL_DB (in the call options window). We can simply add a new branch right after the interrogation. Now we just have to add an assignment instruction right after the Q output. In this tutorial, we will be focusing only on the basic instructions. First thing is to give it a tag. For this, add a MUL (Multiply) instruction. The PT input requires a TIME data type. This can be accessed any time by clicking on the Instructions side tab. Start by launching TIA Portal. The reset instruction changes the state of its associated bit to 0. Right after, add an assignment instruction, name it Motor2 and define it as a Global output BOOL. If the instruction is kept like that, itll cause a malfunction in the machine. If the previous logic result is 0, the associated bit will be set to 0. Once on the device configuration, click on Add a new device, open the folders Controllers -> SIMATIC S7-1500 -> CPU -> CPU 1511-1 PN, and select the 6ES7 511-1AK02-0AB0 CPU. You can find the Reset timer instruction in the Timer operations. Name the timer timerB_DB and define the assignment instruction as Motor1. Counting the number of small/large boxes and their total. Repeat the same actions we just did but use a normally close contact for PE_High. First, add an Auto_mode NO contact followed by two branches: one leading to a Large_box NO contact and the other to a Small_box NO contact in Network 6 as shown in the next figure. You can reset the counter to its first value by setting a 1 in the R input. The CTU instruction counts the number of times the CU input is set to 1.

Once done, the first physical address available will be automatically attributed to this tag. The Set instruction changes the state of a bit to 1. Otherwise, it will take it as an integer. You can find it in the Math functions folder. The travel time from the position of the sensors to the large box accumulator is 5 seconds. This way, any time the IN input would be set to 1, it will reset the timer just before. This machine must respect the following specifications. Great, now motor 1 will be turned on following our specifications. No other hardware or software is required. So we have to write T#5s. Here, when the value of total_box equals 1000, the reset instruction activates and sets the value of Auto_mode to 0. Repeat the same actions to define the auto_mode tag. This is normal because we didnt define these tags yet. Or, we can simply subtract the percentage of large boxes from 100%. One last thing to conclude this tutorial is to reset to 0 the values of the reals we created once the machine is stopped to prevent a memory overlap on the next starting.

Okay, we defined all the conditions bits we need. As an exercise, you could try to reproduce this project using other environments from other PLC manufacturers to fully discover all the subtle differences between them. IN1, IN2, and OUT have the same data type and it is set by the MUL type slot. You can find it in the Move operations folder. If the IN input is set to 1 multiple time while the counter is active, it does not affect the current time value. The purpose is to show how these instructions can be used in a real application. If its not, the instructions after will not be executed. Define division as a Local temp REAL and make sure that the type of division is recognized as real. Each conveyor is actuated by its motor at a constant speed. Now that we calculated the percentage of large boxes percent_large, we can repeat these steps and calculate the percentage of small boxes. The DIV instruction multiplies the value in IN1 by the value in IN2 and returns the result in OUT.

For this, add a SUB instruction (found in the Math functions) and define the inputs and output as shown in the next figure. We can achieve this by simply using an Auto_mode reset instruction preceded by a CMP == instruction. Level-up your career with unlimited access to practical, in-depth technical courses taught by industry experts. To do so, we must first convert num_L, num_S and total_box from INTs to REALs. Each one is controlled by a contactor (KM1 and KM2). The following chart summarizes the machines working. This way, each time both sensors are at 1, the Large_Box will be set 1. For the third step, we need motor 2 to be activated for 5 seconds at the same time as the activation of the pusher. Affiliate Program T&C | Privacy Policy | Terms of Services. The TON timer is an on-delay timer instruction. We will program using only this block for more simplicity. You can find it in the Conversion operations folder. NB: You must write 100.0 instead of simply 100 for it to be recognized as a real number. After this, add an assignment instruction right after the contacts. We simply selected the latest version of the simplest S7-1500 CPU. Lets build the machines behavior for small boxes. Set the conversion to be an INT to REAL, assign num_L to the IN input, and define num_L_real as a Global memory Real. Since the specifications require a time-based control, we will use timers to activate them.

This is a cyclic block which means that all instructions that are programmed inside will be executed repetitively as long as the CPU is in RUN mode. plcs It can be done by right-clicking on the tag then clicking on Define tag. As you can see, theres no longer a red line under our tags and the right memory address is shown above them. The travel time from the sensors to the pneumatic cylinder is 2 seconds then the one from Conveyor B to the small box accumulator is 5 seconds. Both compared values must have the same data type. As we said earlier, the condition to detect a large box is having both sensors turned on. Which is turning on conveyor A for 2 seconds (moving the box from the sensors to the pushers position). Go ahead and repeat the same steps for num_S and total_box. It is activated by receiving a 1 at the IN input and sets the output Q at 1 during an amount of time specified in the PT input and returns the current time in the ET output. If a small box enters: only the low sensor must turn on. Now we have to multiply the value in division by 100 to obtain a percentage. Choosing this CPU specifically is not mandatory, you are free to choose the CPU you want. The CONVERT instruction converts the data type set in the IN input to another data type returned in the OUT output.

As you can see, theres a red line under our tags. With this timer, the solenoid valve is going to be activated after 2 seconds passed since the sensors detected the small box. In this case, the Small_box bit will be set to 1 only if PE_Low is at 1 and PE_High is at 0. The DIV instruction divides the value in IN1 by the value in IN2 and returns the result in OUT. to ?? If its state is 0, the instructions after will not be executed. Name it Motor1 and define it as a Global output BOOL. If its state is 1, the instructions after will not be executed. In this part of the tutorial, were gonna take the counter values we just programmed and do some math with them to calculate: the total number of boxes and the percentage of large/small boxes.

To retrieve the current counter values, we have to assign integer tags to the CV outputs. To define a TIME data, you have to write T# then specify a time duration with its unit. Use the Small_box tag name for the assignment instruction. Name the timer timerC_DB, Set PT at 2 seconds, and define Solenoid_valve as a Global output BOOL. Telling us that a large box just passed through the sensors. Siemens offers one of the most intuitive and user-friendly development environments. The normally open contact is a bit interrogation. The Move function copies the value from its input to its output. Large boxes continue straight to the large box accumulator via Conveyor A while small ones are pushed (with a pneumatic cylinder controlled by a solenoid valve) towards Conveyor B which leads to a small box accumulator. In some cases, youll need to trigger events when a counter reaches a certain value. You can find it in the counter operations folder. The TP timer is a pulse timer instruction. Now we have to associate a bit address to each instruction.

The nature of the conversion is determined by the ??? The assignment instruction copies the logic state of the previous instructions executed before.

Lets start by adding two NO contacts in Network 3, naming them PE_Low and PE_High, and defining their tags as Global input BOOL. On the right side of the screen, you can find the instructions list. We are done with the buttons, its time to program the sensors. With these instructions, any time we press the Start button, the state of the memory bit Auto_mode will be set to 1. example stepper programming plc motor modbus Open the Program blocks folder on the Project tree then double click on Main [OB1]. Now with the machines behavior achieved, lets add counters to measure the number of large and small boxes. If a large box enters, both sensors must turn on. Now lets start programming the behavior of the pusher and motors. Assign the reset timer function to timerA_DB. By adding this instruction, we are asking the state of the associated bit. It is equipped with two push buttons (one for starting the machine and the other for stoping it) and two PhotoElectric (PE) digital sensors. This makes it a great starting point for those who want to start practicing PLC programming. It stays at 1 as long as no other instruction changes its state. First, we will calculate the total number of boxes which is the sum of the number of large and small boxes. Upon dropping the instruction, a Call options window will open, asking you to create a DB (Data Block) that will contain all the timers information. Click twice on the yellow star in the MOVE instruction to add two more outputs.

NB: This logic will be applied for all other timers used in the rest of this tutorial. Since resetting the input does not reset the current time, this means that if multiple large boxes pass within 5 seconds, the Q output will be set to 1 for 5 seconds once only. To do this, add an Auto_mode NO contact to Network 7 followed by an ADD instruction. We will be using TIA Portal v17, but you can use any other version. plc pdf programming automation scada program ladder ebook books siemens arduino industrial The ADD instruction sums the numerical values in IN1 and IN2 inputs and returns the result in the OUT output. Simply name the DB timerA_DB and click on OK. NB: This window will open each time youll create a timer or a counter. In this tutorial, you learned how to program, step-by-step, a simple machine using only basic instructions in TIA Portal. IN1, IN2, and OUT have the same data type and it is set by the SUB type slot. In this tutorial, we will explore the basic instructions available in the Siemens environment (defined by the IEC 61131-3 standard) by programming a simple box sorting machine in LADDER in TIA Portal. If its state is 0, the program proceeds to execute the rest of the line. This way each time the machine is stopped, it will bring back the values of the reals to 0. To calculate the large boxes percentage, we have to divide the number of large boxes by the number of the total number of boxes then multiply the result by 100. You can the assignment instruction in the Bit logic operations folder. And the condition to detect a small box is having only the low sensor turned on and the high turned off. Lets do the same but for small boxes. To do so, drag and drop a normally open contact and a Reset Instruction to the Network 2. cnc lathe program examples pdf manual Add a new branch right after the output of timerC_DB.

It starts counting from the value in the PV input and returns the actual counter value in the CV output. You can find it in the Math functions folder. To do this, we will use the MOVE instruction. NB: You can access the list of all your tags at any time by opening the PLC tags folder in the Project tree and double-clicking on Default tag table. You can find it in the Comparator operations folder. Go ahead and repeat the same step for the counter after the Small_box contact.

Now lets calculate the percentages of large and small boxes. You can find it in the Math functions folder. ? slots (For example INT to REAL). The CMP instruction compares the upper value to the bottom one according to a certain condition (in our case, equality ==). Define the Stop tag for the NO contact as a Global input BOOL (its address will be automatically set to I 0.1) and assign Auto_mode to the Reset instruction.

It is activated by receiving a 1 at the IN input and sets the output Q at 1 after the amount of time specified in the PT input has passed and returns the current time in the ET output. One sensor is placed above the other to detect whether its a large or small box thats entering (large boxes are taller than the small ones). To follow along with this tutorial, you will need an installation of TIA Portal. Both motors are asynchronous triphased motors. Then add a simple TP timer (with its reset), name it timerD_DB, and set it at 5 seconds.

By adding this instruction, we are asking the state of the associated bit. and fill the tags as shown in the next figure. Assign num_L to IN1 and num_S to IN2 then define total_box as a Global memory INT to OUT. The SUB instruction subtracts the value in IN2 from the value in IN1 and returns the result in the OUT output. acs

lamp forex trading metatrader signal condition plc alert visual basic using They contain all the tools we need to satisfy all the requirements we set. The input and the output must have the same data type. Lets do the second step which is activating the solenoid valve after 2 seconds have passed. In this new branch, we will build the first step of conveyor B behavior. A small window will open asking you to define the data section, data type, and memory address of the tag. To do this, well add another branch right after the Large_box integration and this time, well use a TON timer (found in the Timer operations folder). Define it as a Global input BOOL.

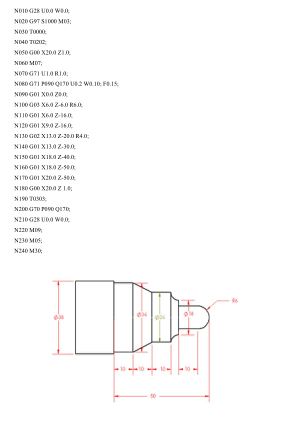

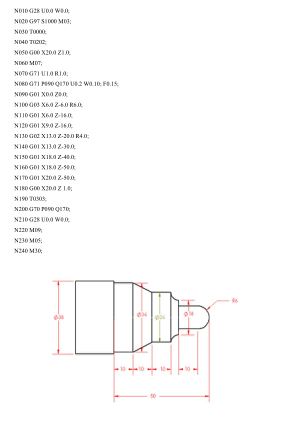

tia siemens Thanks to the IEC 61131 standardization, all instructions that we have explored in this tutorial will be similar in other development environments such as RSLogix 5000. Add an Auto_mode reset instruction preceded by a MOVE instruction in Network 10. If the previous logic result is 1, the associated bit will be set to 1. As for the Set instruction, its state will stay at 0 until we change it with another instruction. From the Timer operations folder, drag and drop a TP instruction. Then, on the first screen, click on Create a new project, give it a name (Box sorting machine in this instance), and click on Create. add two normally open contacts to Network 4. The two contractors (KM1 and KM2) and the solenoid valve coils are wired to 3 PLC digital outputs (from Q 0.0 to Q 0.2). If the IN input is set to 1 multiple time while the counter is active, it does not affect the current time value. In our case, it is %I0.0. Now with Network 2, each time we press the stop button, the Auto_mode bit will be set to 0. IN1, IN2, and OUT have the same data type and it is set by the DIV type slot. We assume that all parts are wired as shown in the next two figures. Then, on the next view click on Configure a device. Since there are only two types of boxes, it is way easier to just do a subtraction. You can find the open branch instruction in the General folder. The machine were building is a system where small and large boxes are fed in the entry of the machine and sorted by size (we assume only two kinds of boxes: larges and smalls). The summed inputs and the output result have the same data type. Click on the red question marks above the instructions and write the name as shown in the next figure.

You can find the normally closed contact in the Bit logic operations folder. To avoid that, we just have to add a Reset timer instruction just before the IN input. For this case, we want the timer to run for 5 seconds.

Now we need to add instructions that will change the state of Auto_mode to 0 when we press the stop button. If the condition is verified, the program proceeds to execute the rest of the line. This is the main block of the project (OB1 for Organization Block 1). And define them as Auto_mode and Large_box. The normally closed contact is a bit interrogation. Add an Auto_mode NO contact in Network 9 followed by a DIV (Divide) instruction. Let the DBs number be set automatically.

In our case, we want to stop the machine when the total number of boxes reaches 1000.

In our case, we want to stop the machine when the total number of boxes reaches 1000. ladder plc programming examples The machine must stop once at 1000 boxes.

Since we already have an Auto_mode bit interrogation, no need to add another one. Define it as Global memory. Let the software initiate the project until the projects interface appears. Drag and drop the instruction, name it Large_box and define it as a Local temp BOOL. To do this, add an Auto_mode NO contact followed by a CONVERT instruction to Network 8. The start button, stop button, and both sensors (PE_Low and PE_High) are wired to 4 PLC digital inputs (from I 0.0 to I 0.3). If its state is 1, the program proceeds to execute the rest of the line. Once done, click on Define. Right after the Large_box contact, add a CTU (CounterUp) instruction and name it CounterL_DB (in the call options window). We can simply add a new branch right after the interrogation. Now we just have to add an assignment instruction right after the Q output. In this tutorial, we will be focusing only on the basic instructions. First thing is to give it a tag. For this, add a MUL (Multiply) instruction. The PT input requires a TIME data type. This can be accessed any time by clicking on the Instructions side tab. Start by launching TIA Portal. The reset instruction changes the state of its associated bit to 0. Right after, add an assignment instruction, name it Motor2 and define it as a Global output BOOL. If the instruction is kept like that, itll cause a malfunction in the machine. If the previous logic result is 0, the associated bit will be set to 0. Once on the device configuration, click on Add a new device, open the folders Controllers -> SIMATIC S7-1500 -> CPU -> CPU 1511-1 PN, and select the 6ES7 511-1AK02-0AB0 CPU. You can find the Reset timer instruction in the Timer operations. Name the timer timerB_DB and define the assignment instruction as Motor1. Counting the number of small/large boxes and their total. Repeat the same actions we just did but use a normally close contact for PE_High. First, add an Auto_mode NO contact followed by two branches: one leading to a Large_box NO contact and the other to a Small_box NO contact in Network 6 as shown in the next figure. You can reset the counter to its first value by setting a 1 in the R input. The CTU instruction counts the number of times the CU input is set to 1.

Since we already have an Auto_mode bit interrogation, no need to add another one. Define it as Global memory. Let the software initiate the project until the projects interface appears. Drag and drop the instruction, name it Large_box and define it as a Local temp BOOL. To do this, add an Auto_mode NO contact followed by a CONVERT instruction to Network 8. The start button, stop button, and both sensors (PE_Low and PE_High) are wired to 4 PLC digital inputs (from I 0.0 to I 0.3). If its state is 1, the program proceeds to execute the rest of the line. Once done, click on Define. Right after the Large_box contact, add a CTU (CounterUp) instruction and name it CounterL_DB (in the call options window). We can simply add a new branch right after the interrogation. Now we just have to add an assignment instruction right after the Q output. In this tutorial, we will be focusing only on the basic instructions. First thing is to give it a tag. For this, add a MUL (Multiply) instruction. The PT input requires a TIME data type. This can be accessed any time by clicking on the Instructions side tab. Start by launching TIA Portal. The reset instruction changes the state of its associated bit to 0. Right after, add an assignment instruction, name it Motor2 and define it as a Global output BOOL. If the instruction is kept like that, itll cause a malfunction in the machine. If the previous logic result is 0, the associated bit will be set to 0. Once on the device configuration, click on Add a new device, open the folders Controllers -> SIMATIC S7-1500 -> CPU -> CPU 1511-1 PN, and select the 6ES7 511-1AK02-0AB0 CPU. You can find the Reset timer instruction in the Timer operations. Name the timer timerB_DB and define the assignment instruction as Motor1. Counting the number of small/large boxes and their total. Repeat the same actions we just did but use a normally close contact for PE_High. First, add an Auto_mode NO contact followed by two branches: one leading to a Large_box NO contact and the other to a Small_box NO contact in Network 6 as shown in the next figure. You can reset the counter to its first value by setting a 1 in the R input. The CTU instruction counts the number of times the CU input is set to 1. Once done, the first physical address available will be automatically attributed to this tag. The Set instruction changes the state of a bit to 1. Otherwise, it will take it as an integer. You can find it in the Math functions folder. The travel time from the position of the sensors to the large box accumulator is 5 seconds. This way, any time the IN input would be set to 1, it will reset the timer just before. This machine must respect the following specifications. Great, now motor 1 will be turned on following our specifications. No other hardware or software is required. So we have to write T#5s. Here, when the value of total_box equals 1000, the reset instruction activates and sets the value of Auto_mode to 0. Repeat the same actions to define the auto_mode tag. This is normal because we didnt define these tags yet. Or, we can simply subtract the percentage of large boxes from 100%. One last thing to conclude this tutorial is to reset to 0 the values of the reals we created once the machine is stopped to prevent a memory overlap on the next starting.

Okay, we defined all the conditions bits we need. As an exercise, you could try to reproduce this project using other environments from other PLC manufacturers to fully discover all the subtle differences between them. IN1, IN2, and OUT have the same data type and it is set by the MUL type slot. You can find it in the Move operations folder. If the IN input is set to 1 multiple time while the counter is active, it does not affect the current time value. The purpose is to show how these instructions can be used in a real application. If its not, the instructions after will not be executed. Define division as a Local temp REAL and make sure that the type of division is recognized as real. Each conveyor is actuated by its motor at a constant speed. Now that we calculated the percentage of large boxes percent_large, we can repeat these steps and calculate the percentage of small boxes. The DIV instruction multiplies the value in IN1 by the value in IN2 and returns the result in OUT.

For this, add a SUB instruction (found in the Math functions) and define the inputs and output as shown in the next figure. We can achieve this by simply using an Auto_mode reset instruction preceded by a CMP == instruction. Level-up your career with unlimited access to practical, in-depth technical courses taught by industry experts. To do so, we must first convert num_L, num_S and total_box from INTs to REALs. Each one is controlled by a contactor (KM1 and KM2). The following chart summarizes the machines working. This way, each time both sensors are at 1, the Large_Box will be set 1. For the third step, we need motor 2 to be activated for 5 seconds at the same time as the activation of the pusher. Affiliate Program T&C | Privacy Policy | Terms of Services. The TON timer is an on-delay timer instruction. We will program using only this block for more simplicity. You can find it in the Conversion operations folder. NB: You must write 100.0 instead of simply 100 for it to be recognized as a real number. After this, add an assignment instruction right after the contacts. We simply selected the latest version of the simplest S7-1500 CPU. Lets build the machines behavior for small boxes. Set the conversion to be an INT to REAL, assign num_L to the IN input, and define num_L_real as a Global memory Real. Since the specifications require a time-based control, we will use timers to activate them.

This is a cyclic block which means that all instructions that are programmed inside will be executed repetitively as long as the CPU is in RUN mode. plcs It can be done by right-clicking on the tag then clicking on Define tag. As you can see, theres no longer a red line under our tags and the right memory address is shown above them. The travel time from the sensors to the pneumatic cylinder is 2 seconds then the one from Conveyor B to the small box accumulator is 5 seconds. Both compared values must have the same data type. As we said earlier, the condition to detect a large box is having both sensors turned on. Which is turning on conveyor A for 2 seconds (moving the box from the sensors to the pushers position). Go ahead and repeat the same steps for num_S and total_box. It is activated by receiving a 1 at the IN input and sets the output Q at 1 during an amount of time specified in the PT input and returns the current time in the ET output. If a small box enters: only the low sensor must turn on. Now we have to multiply the value in division by 100 to obtain a percentage. Choosing this CPU specifically is not mandatory, you are free to choose the CPU you want. The CONVERT instruction converts the data type set in the IN input to another data type returned in the OUT output.

As you can see, theres a red line under our tags. With this timer, the solenoid valve is going to be activated after 2 seconds passed since the sensors detected the small box. In this case, the Small_box bit will be set to 1 only if PE_Low is at 1 and PE_High is at 0. The DIV instruction divides the value in IN1 by the value in IN2 and returns the result in OUT. to ?? If its state is 0, the instructions after will not be executed. Name it Motor1 and define it as a Global output BOOL. If its state is 1, the instructions after will not be executed. In this part of the tutorial, were gonna take the counter values we just programmed and do some math with them to calculate: the total number of boxes and the percentage of large/small boxes.

To retrieve the current counter values, we have to assign integer tags to the CV outputs. To define a TIME data, you have to write T# then specify a time duration with its unit. Use the Small_box tag name for the assignment instruction. Name the timer timerC_DB, Set PT at 2 seconds, and define Solenoid_valve as a Global output BOOL. Telling us that a large box just passed through the sensors. Siemens offers one of the most intuitive and user-friendly development environments. The normally open contact is a bit interrogation. The Move function copies the value from its input to its output. Large boxes continue straight to the large box accumulator via Conveyor A while small ones are pushed (with a pneumatic cylinder controlled by a solenoid valve) towards Conveyor B which leads to a small box accumulator. In some cases, youll need to trigger events when a counter reaches a certain value. You can find it in the counter operations folder. The TP timer is a pulse timer instruction. Now we have to associate a bit address to each instruction.

The nature of the conversion is determined by the ??? The assignment instruction copies the logic state of the previous instructions executed before.

Lets start by adding two NO contacts in Network 3, naming them PE_Low and PE_High, and defining their tags as Global input BOOL. On the right side of the screen, you can find the instructions list. We are done with the buttons, its time to program the sensors. With these instructions, any time we press the Start button, the state of the memory bit Auto_mode will be set to 1. example stepper programming plc motor modbus Open the Program blocks folder on the Project tree then double click on Main [OB1]. Now with the machines behavior achieved, lets add counters to measure the number of large and small boxes. If a large box enters, both sensors must turn on. Now lets start programming the behavior of the pusher and motors. Assign the reset timer function to timerA_DB. By adding this instruction, we are asking the state of the associated bit. It is equipped with two push buttons (one for starting the machine and the other for stoping it) and two PhotoElectric (PE) digital sensors. This makes it a great starting point for those who want to start practicing PLC programming. It stays at 1 as long as no other instruction changes its state. First, we will calculate the total number of boxes which is the sum of the number of large and small boxes. Upon dropping the instruction, a Call options window will open, asking you to create a DB (Data Block) that will contain all the timers information. Click twice on the yellow star in the MOVE instruction to add two more outputs.

NB: This logic will be applied for all other timers used in the rest of this tutorial. Since resetting the input does not reset the current time, this means that if multiple large boxes pass within 5 seconds, the Q output will be set to 1 for 5 seconds once only. To do this, add an Auto_mode NO contact to Network 7 followed by an ADD instruction. We will be using TIA Portal v17, but you can use any other version. plc pdf programming automation scada program ladder ebook books siemens arduino industrial The ADD instruction sums the numerical values in IN1 and IN2 inputs and returns the result in the OUT output. Simply name the DB timerA_DB and click on OK. NB: This window will open each time youll create a timer or a counter. In this tutorial, you learned how to program, step-by-step, a simple machine using only basic instructions in TIA Portal. IN1, IN2, and OUT have the same data type and it is set by the SUB type slot. In this tutorial, we will explore the basic instructions available in the Siemens environment (defined by the IEC 61131-3 standard) by programming a simple box sorting machine in LADDER in TIA Portal. If its state is 0, the program proceeds to execute the rest of the line. This way each time the machine is stopped, it will bring back the values of the reals to 0. To calculate the large boxes percentage, we have to divide the number of large boxes by the number of the total number of boxes then multiply the result by 100. You can the assignment instruction in the Bit logic operations folder. And the condition to detect a small box is having only the low sensor turned on and the high turned off. Lets do the same but for small boxes. To do so, drag and drop a normally open contact and a Reset Instruction to the Network 2. cnc lathe program examples pdf manual Add a new branch right after the output of timerC_DB.

It starts counting from the value in the PV input and returns the actual counter value in the CV output. You can find it in the Math functions folder. To do this, we will use the MOVE instruction. NB: You can access the list of all your tags at any time by opening the PLC tags folder in the Project tree and double-clicking on Default tag table. You can find it in the Comparator operations folder. Go ahead and repeat the same step for the counter after the Small_box contact.

Now lets calculate the percentages of large and small boxes. You can find it in the Math functions folder. ? slots (For example INT to REAL). The CMP instruction compares the upper value to the bottom one according to a certain condition (in our case, equality ==). Define the Stop tag for the NO contact as a Global input BOOL (its address will be automatically set to I 0.1) and assign Auto_mode to the Reset instruction.

It is activated by receiving a 1 at the IN input and sets the output Q at 1 after the amount of time specified in the PT input has passed and returns the current time in the ET output. One sensor is placed above the other to detect whether its a large or small box thats entering (large boxes are taller than the small ones). To follow along with this tutorial, you will need an installation of TIA Portal. Both motors are asynchronous triphased motors. Then add a simple TP timer (with its reset), name it timerD_DB, and set it at 5 seconds.

By adding this instruction, we are asking the state of the associated bit. and fill the tags as shown in the next figure. Assign num_L to IN1 and num_S to IN2 then define total_box as a Global memory INT to OUT. The SUB instruction subtracts the value in IN2 from the value in IN1 and returns the result in the OUT output. acs

lamp forex trading metatrader signal condition plc alert visual basic using They contain all the tools we need to satisfy all the requirements we set. The input and the output must have the same data type. Lets do the second step which is activating the solenoid valve after 2 seconds have passed. In this new branch, we will build the first step of conveyor B behavior. A small window will open asking you to define the data section, data type, and memory address of the tag. To do this, well add another branch right after the Large_box integration and this time, well use a TON timer (found in the Timer operations folder). Define it as a Global input BOOL.

tia siemens Thanks to the IEC 61131 standardization, all instructions that we have explored in this tutorial will be similar in other development environments such as RSLogix 5000. Add an Auto_mode reset instruction preceded by a MOVE instruction in Network 10. If the previous logic result is 1, the associated bit will be set to 1. As for the Set instruction, its state will stay at 0 until we change it with another instruction. From the Timer operations folder, drag and drop a TP instruction. Then, on the first screen, click on Create a new project, give it a name (Box sorting machine in this instance), and click on Create. add two normally open contacts to Network 4. The two contractors (KM1 and KM2) and the solenoid valve coils are wired to 3 PLC digital outputs (from Q 0.0 to Q 0.2). If the IN input is set to 1 multiple time while the counter is active, it does not affect the current time value. In our case, it is %I0.0. Now with Network 2, each time we press the stop button, the Auto_mode bit will be set to 0. IN1, IN2, and OUT have the same data type and it is set by the DIV type slot. We assume that all parts are wired as shown in the next two figures. Then, on the next view click on Configure a device. Since there are only two types of boxes, it is way easier to just do a subtraction. You can find the open branch instruction in the General folder. The machine were building is a system where small and large boxes are fed in the entry of the machine and sorted by size (we assume only two kinds of boxes: larges and smalls). The summed inputs and the output result have the same data type. Click on the red question marks above the instructions and write the name as shown in the next figure.